Induction Motor Slot Pole Combinations

There are many much more interesting questions related to the pole number of induction motors, e.g.:

1. Does the induction motor supplied by the main grid (say, 50 Hz) increases its torque capability in 'p' times with growing pole number 'p' since its speed decreases in 'p' time (like in a gearbox)?

2. Let's we have an induction motor with p=2 and feed it from 50 Hz grid. Then we re-connect the winding coils to arrange p=4 and feed if grow 100 Hz grid. Are performances of these two motors different or the same? Please note excluding frequency and inter-coil connections all remained the same.

It depends on the required speed. n (rpm) = (60 x f) / N where:- f = frequency and N = number of pole pairs. The 60 is there to convert from revolutions per second to revolutions per minute as the frequency is in cycles per second. Pole pairs is there because that any pole must be constructed in a pairs top and bottom / left right, so with one cycle it will move half the distance.

If you are using 50Hz and have a two pole motor 60 x 50 / 1 = 3000 rpm. The induction motor will run at a slight less speed due to 'slip' which is what gives the motor its torque. For example 5.5kW, 400v, 2 pole motor will run at approximately 2880 rpm.

For a four pole machine, 60 x 50 / 2 = 1500 rpm so the same size motor at 5.5kW, 400v but 4 poles will have a nominal speed of 1500rpm but will run near 1455 rpm.

When selecting a three phase motor, the number of poles is chosen to achieve the speed of rotation that you require. Here are two tables, one for a 50 Hz power supply and one for a 60 Hz power supply:

The formula is n = 60 x f /p where n = synchronous speed; f = supply frequency & p = pairs of poles per phase. The actual running speed is the synchronous speed minus the slip speed.

For a 50 Hz three phase supply:

2 poles or 1 pair of poles = 3,000 RPM (minus the slip speed = about 2,750 RPM or 6 -7% n)

4 poles or 2 pairs of poles = 1,500 RPM

6 poles or 3 pairs of poles = 1,000 RPM

8 poles or 4 pairs of poles = 750 RPM

10 poles or 5 pairs of poles = 600 RPM

12 poles or 6 pairs of poles = 500 RPM

16 poles or 8 pairs of poles = 375 RPM

Induction Motor Slot Pole Combinations List

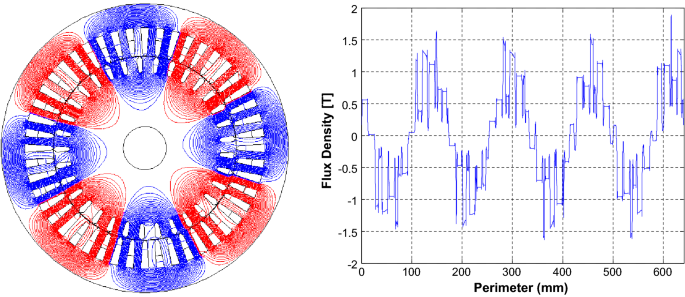

Optimal slot/pole and flux-barrier layer number combinations for synchronous reluctance machines Abstract: AC synchronous reluctance machine (SynRM) or permanent magnet assisted synchronous reluctance machine presently receives a great deal of interest, since there is less or even no rare earth permanent magnet in the rotor. During grid motor starting from zero rpm, this starting current flow is in the upper part of the bar close to the rotor OD. (due to the skin effect of current penetration). AS the motor increases speed the bar current is distributed down in the lower part of the bar & the frequency seen by the bar decreases (decreasing slip). An optimal stator and rotor pole numbers until 1. Feasible combinations for a three-phase FSPM machines with magnets are given in (1) 1. N s =6k 1,k 1 ∈ N∗ N r = N s ±k 2,k 2 ∈ N∗ (1) N s is the slot and magnet numbers, which must be even and N r is the rotor pole number. Thus, for a 12-slot machine, any rotor could potentially be. Synchronous machine armatures and induction – motor stators above a few kW, are wound with double layer windings if the number of slots per pole per phase 𝒒𝒒= 𝑺𝑺 𝒎𝒎𝑷𝑷. Is an integer, then the winding is called an. Integral-slot winding in case the number of slots per pole per phase, q is not an integer, the. The induction motor will run at a slight less speed due to 'slip' which is what gives the motor its torque. For example 5.5kW, 400v, 2 pole motor will run at approximately 2880 rpm. For a four pole machine, 60 x 50 / 2 = 1500 rpm so the same size motor at 5.5kW, 400v but 4 poles will have a nominal speed of 1500rpm but will run near 1455 rpm.

For a 60 Hz three phase supply:

Induction Motor Slot Pole Combinations Chart

2 poles or 1 pair of poles = 3,600 RPM (minus the slip speed = about 2,750 RPM or 6 -7% n)

4 poles or 2 pairs of poles = 1,800 RPM

6 poles or 3 pairs of poles = 1,200 RPM

8 poles or 4 pairs of poles = 900 RPM

10 poles or 5 pairs of poles = 720 RPM

12 poles or 6 pairs of poles = 600 RPM

16 poles or 8 pairs of poles = 450 RPM

Induction Motor Slot Pole Combinations Diagram

Induction Motor Slot Pole Combinations Generator

To determine the number of poles, you can read the data plate directly or calculate it from the RPM stated on the data plate or you can count the coils and divide by 3 (poles per phase) or by 6 (pairs of poles per phase). Where the power of the induction motor is constant, the torque increases at the rate that the speed decreases.

With the advent of variable frequency drive (VFD), you can have any frequency / rated volts you desire. I often see name plates with things like 575VAC, 42.5 Hz etc. When these 'specials' are made I usually see 6 pole machines - but that may be just a manufacturer's preference.